|

|

1. Adopted digital power source and A/D card instead of old analog power source, frequency meter, amperemeter, voltmeter and wattmeter.

2. Perfectly match Windows system, easy to operate.

3. Test Samples: hot&cold rolled silicon steel(oriented or non-oriented), permalloy, amorphous alloy and nanocrystalline.

4. Sample shape: ribbon and chip open samples, ring, E&U shape etc closed-circuit samples.

5. Open circuit samples adopt Epstein Square to form closed magnetic circuit, it can also select permeameter. Closing sample can be put under direct winding measurement, finished transformer can be also put under direct measurement.

6. A non-load transformer included a sample core, a magnetizing turns(N1) and a measuring turns(N2).

7. N1 connected non-inductive resistance, to define the magnetizing current by testing the descending voltage of the non-inductive resistance to get the field strength. Peak value lock feedback by digits, field lock accuracy is 0.5%.

8. Get flux induction by digital analyzing the N2 voltage,Peak value lock feedback by digits, induction lock accuracy is 0.2%.

9. Power source and sampling amplifier embedded in one case with simple interfaces: a computer-connect inferface RS232, two-way voltage signal connect to A/D card.

10. Use voltammetry and DDA to test magnetic property like dynamic hysteresis loop, Ps, Jm, Hm, Ss, μa, loss angle, Br and Hc.

11. Constantly test over 255 points, each one cost 30 seconds, fixed frequency, lock Bm or lock Hm modes optional.

1. Perfectly match Windows 7. English & English-Chinese version optional. Easy to operate.

2. Lock Bm or Lock Hm oprtioal, multiple choices.

3. Full-automatic operation. Intelligent auto-recognition.

4. Measuring process in real time monitoring, can be suspended at any time.

5. Automatic calculating. Be able to do results conversion according to temperature.

6. Adopted data base format, directly print or output test results to Excel.

7. Document function: data save, data delete, remove whole data etc.

8. Reports include full sample data, sample parameters, device parameters and test schemes. Text format, easy to output.

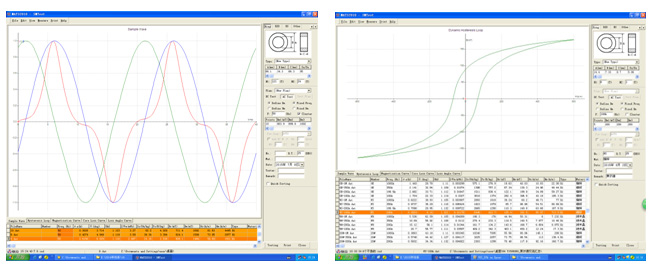

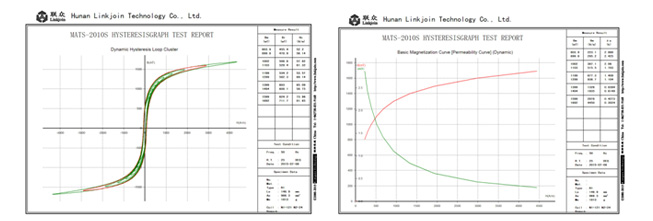

9. Display I(t), U(t), B(t)curves and B(H) hysteresis loop. Coordinates of each points on the curves canbe also displayed.

10. After multiple points clustering, display B(H) hysteresis loop cluster, B(H) magnetizing curve, μa(H) permeability curve and Ps(B) loss curve. Coordinates of each points on the curves canbe also displayed.

11. Set B(H) magnetizing curve and Ps(B) together on one chart, easy to analysis.

12. Set limits according to μa, Ps, Bm, Br, Hc and Hm. Define and color the passed results.

13. Support various kinds of printers. Test reports perfectly match the print sheet.

14. Print preview, easy to adjust the reports size and edge.

15. Print reports directly or convert the report to graphic file JPG.

16. Built-in e-mail sending function.

17. Test reports include full curve graphic, test results, test conditions and sample parameters. Chinese & English version alterable, able to add clients information.

1、According to GB/T 3655-2000,under 50Hz. 60Hz., test 30×300mm silicon steel by 25cm Epstein frame, reports as following:

| Parameters | Ps(%) | Ss(%) | Hrms(%) | Bm(%) | Hm(%) |

| Uncertainty(k=2) | 1 | 1 | 2 | 1 | 2 |

| Repeatability | ± 0.5 | ± 0.5 | ± 1 | ± 0.5 | ± 1 |

| Remarks |

Lock Bm: non oriented Bm≤1.5T Oriented Bm≤1.7T |

Lock Hm:non orientedHm≥1000A/m OrientedHm≥500A/m |

|||

2、According to GB/T 13789-2008,under 50Hz、60Hz,test 500×500mm silicon steel by SST-500 permeameter, reports as following:

| Parameters | Ps(%) | Ss(%) | Hrms(%) | Bm(%) | Hm(%) |

| Uncertainty(k=2) | 1.5 | 1.5 | 2 | 1 | 3 |

| Repeatability | ± 0.5 | ± 0.5 | ± 1 | ± 0.5 | ± 1 |

| Remarks |

Lock Bm: non oriented Bm=0.8~1.5T Oriented Bm=1.0~1.8T |

Lock Hm:non orientedHm≤10000A/m OrientedHm≤1000A/m |

|||

3. According to GB/T 3658-2008,under 50Hz~1kHz,test permalloy, reports as following:

| Parameters | Ps(%) | Ss(%) | Hrms(%) | Bm(%) | Hm(%) |

| Uncertainty(k=2) | 2 | 3 | - | 1 | 3 |

| Repeatability | ± 1.5 | ± 1 | ± 1 | ± 0.5 | ± 0.5 |

| Remarks |

1. Samples should be thin ring, OD/ND<1.25. 2. Demagnetizing before testing and frequency of demagnetizing should be less than or equal to test frequency. 3. Uncertainty is “-”, means there is no requirement in the National Standard. |

||||

| Technical Data | 201M/K50 | 201M/K75 | 201M/10K |

| Max. Output Power | 500 VA sine wave | 750 VA sine wave | 500 VA sine wave |

| Frequency Range | 45 Hz ~ 1000 Hz | 400Hz~10kHz | |

| Frequency Fineness | 1 Hz | ||

| Frequency Error | < 0.05% | ||

| Output Voltage | 0~10V~50V~150V~300V | 0~10V~50V~80V~100V | 0~10V~50V~150V~300V |

| Voltage Fineness | Program Control 1 mV, panel < 0.1%×current range | ||

| Voltage Distortion Factor | Superior to 0.5% | ||

| Voltage Stability | Superior to 0.02% | ||

| Sampling Current | 5mA~20A | 6.33mA~20A | |

| Sampling Voltage | 100mV~400V | 1V~316V | |

| Max. Voltage | 300V | 100V | 300V |

| Max. Current | 10A | 15A | 10A |

| Measurement materials | hot rolling, cold rolling silicon steel materials, permalloy, amorphous and nm crystal. | ||

| Sample shape | ribbon and chip open samples, toroid, E and U closing samples | ||

| Sample size |

For Epstein Frame : 30 mm x(280mm~ 300 mm) For SST-500 Permeameter : 500mm x500mm For customized Permeameter: decided by the Permeameter For E and U closing samples , no physical limitation, size affects the max H field, |

||

| Accuracy (Ps) | 1% (50Hz, Epstein Frame) | 1.5% (50Hz, Permeameter) | 3%(10KHz, ring) |

| Test Time | 30s | 30s | 12s |

| Operating temperature | 23±5℃ | ||

| 201M/K50 | 201M/K75 | 201M/10K |

| 201M Hysteresisgraph | 201M Hysteresisgraph | 201M Hysteresisgraph |

| PC6111 A/D Card | PC 6112 A/D Card | PC 6684 A/D Card |

| Measurement Software | Measurement Software | Measurement Software |

| Computer | Computer | Computer |

| Printer | Printer | Printer |

| Epstein Frame | Epstein Frame | Standard Specimen |

| Square Standard Specimen | Square Standard Specimen |

CAUTION:

As the products of our company are in constant updates, the change of products without pre-notice.

| Model | ES-700 Epstein Fram | ES-200 Mid Band Frame |

| Test Equipment |

|

|

| Environment Temperature | 23℃5±℃ | 23℃5±℃ |

| Humidity | <65% | <65% |

| Equivalent Magnetic Circuit | 940mm | 940mm |

| Winding Turns | N1 700 turns, N2 700 turns | N1 200 turns, N2 200 turns |

| Specimens Size |

Width: 30mm±0.2mm, length: 280~320mm±0.5mm |

Width: 30mm±0.2mm, length: 280~320mm±0.5mm |

| Sample Mass | 240g~1000g | 240g~1000g |

| Applied Frequency | DC~400Hz | 400Hz~10kHz |

| Model | Customized Permeameter | Soft magnet core automatic test tooling |

| Test Equipment |

|

|

| Environment Temperature | 23℃5±℃ | 23℃5±℃ |

| Humidity | <65% | <65% |

| Equivalent Magnetic Circuit |

300mm×300mm, 300mm×30mm, 100mm×100mm, 50mm×50mm |

N/A |

| Winding Turns | N/A | N/A |

| Specimens Size | N/A | N/A |

| Sample Mass | N/A | N/A |

| Applied Frequency | 50Hz and 60Hz | N/A |